■ W = C x T theory

- Machining techniques to bring out the performance of MC machines -

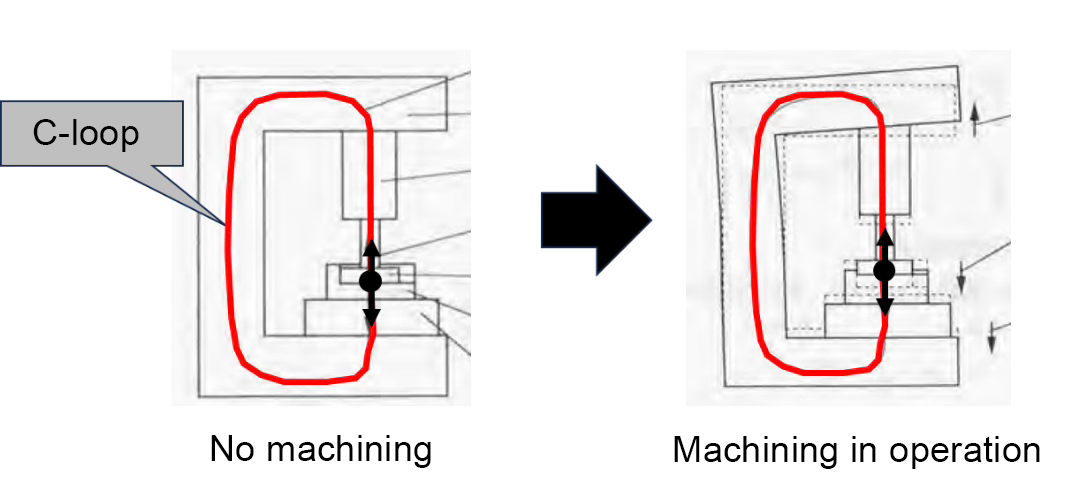

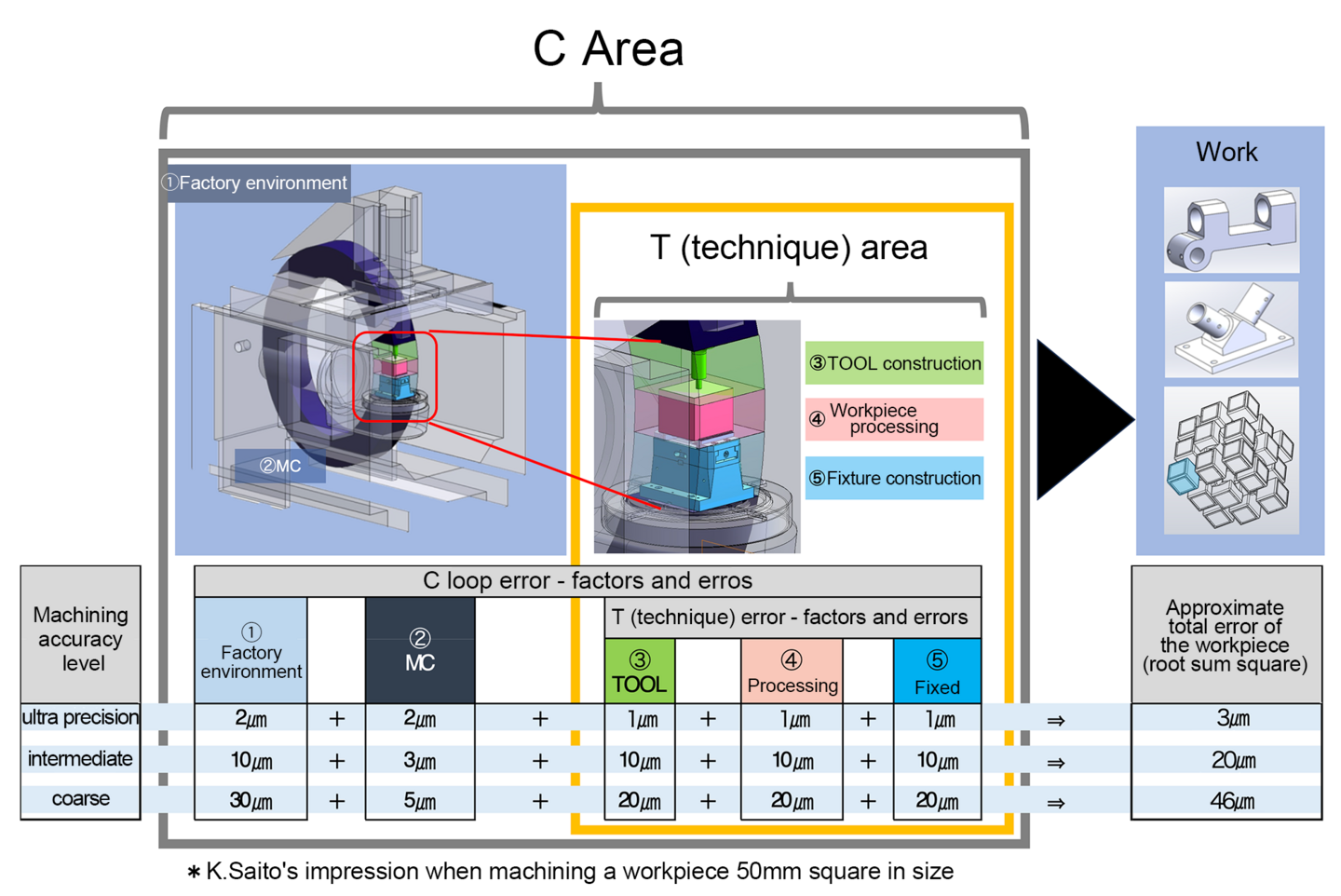

MC machine performance has improved year by year, and the machining accuracy of workpieces has reached a high level. However, even with the same MC machine, differences in the operator's T (technique) can cause differences in workpiece accuracy. Suppressing the vibration of the cutting edge during machining and the expansion and contraction of the cutting edge position leads to improved workpiece accuracy. In order to suppress this vibration and expansion and contraction, it is necessary to clarify and analyze the T area that exists in the C (MC machine + factory environment) loop.

Source: "Research on the integration of force sensing and actuation (1998/Matsumoto Kiyoshi)"

C×T Theory

W (total workpiece machining error) = C (factory environment error + MC error) × T (technique error)

*Technique error (T): Tool construction technology for each workpiece characteristic + workpiece machining technology + fixture construction technology

K. Saito newly defined the T area because the level of precision required for workpieces has increased dramatically compared to 30 years ago, and it has become essential to improve the level of "the technique of the operator who operates the MC machine," which was not previously considered a problem as a cause of error. There are methods to reduce the T (technique) error at machining sites that use MC machines, with little or no cost.

If machining centers with over 12000 revolutions are correctly operated and set up, it is possible to create workpieces with spatial accuracy errors of within ±0.002 mm, even on 5-axis machining machines, which are thought to be difficult to achieve with precision. Incidentally, like MC errors, factory environment errors are beyond the reach of engineers' techniques, so this paper will not mention C-loop errors, which are the accumulation of factory environment errors and MC errors. However, in reality, factory environment errors are greatly affected by the length of the machining time for one program.