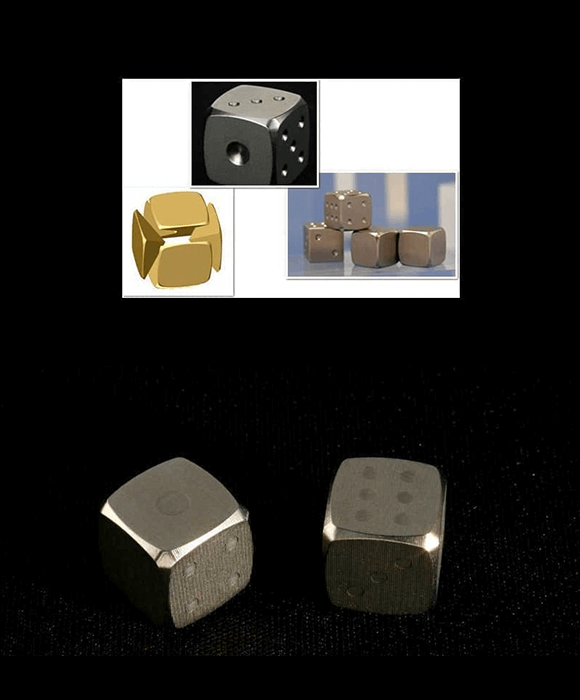

■ "Former" World's Smallect Dice 0.3mm

Length of each side is 0.3mm=300μ. Error±2μ

High level technology is required to grasp a small object and machine all six sides. The smaller the object, the stronger the effect of temperature changes and a wide range of vibrations. The dice we have created have been made possible by the skilled experience and sensibility of our craftsmen, who have been able to minimize such effects.

At present, there is no information available from anywhere in the world about machined dice smaller than this "world's smallest!?" dice.

(Based on a 2005 survey by Iriso Precision) It is no exaggeration to say that these are the smallest dice ever obtained by mankind in recorded history.

They were completed using the world's finest technology, labor, and time, and have been recognized by professors at various national universities.

"Former" World's Smallect Dice 0.3mm

・MC Machine: DMG Mori Seiki NVD4000DCG

・Tool Used: NS TOOL Ball End Mill with Minimum Diameter of φ0.06mm

・Processing Time: 9 hours

・Material: Brass

・Weight: 0.00016 grams (Saitama Industrial Technology Center)

・Dimensional Accuracy: 1 side 0.3mm±2μ

Related article 1 (in Japanese) >>

Related article 2(in Japanese) >>

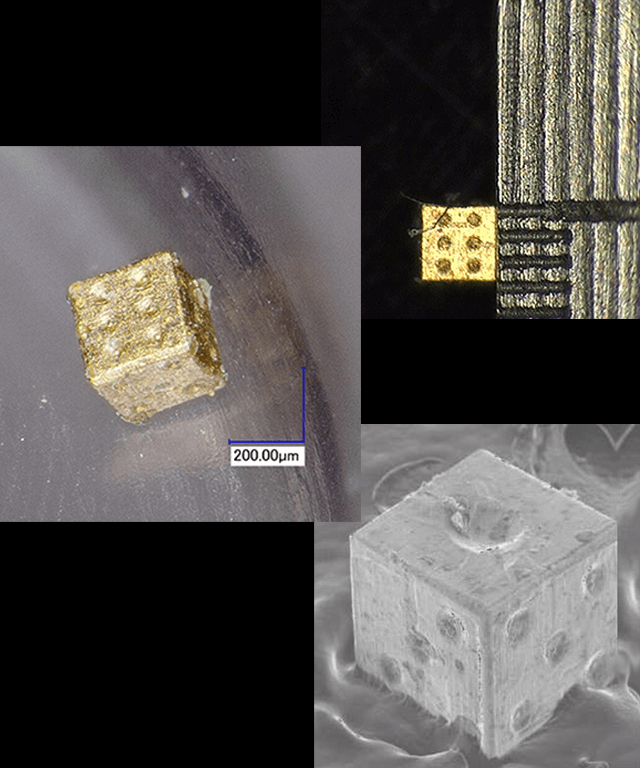

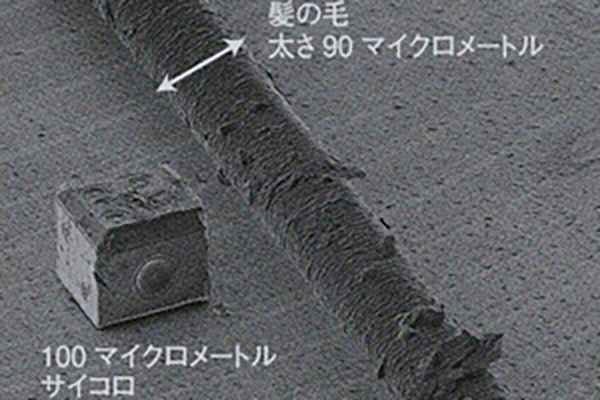

■ "New" World's Smallect Dice 0.1mm

We have succeeded in machining a brass die with dimensions of 100 micrometers on each side, about the thickness of a human hair. Using our in-house developed MICRO HAND and jigs, we were able to control the machining process with a 20-micrometer-diameter end mill to an accuracy of 0.1 micrometers.

By showcasing our high-precision micromachining technology, we expect orders for such use as medical device parts.

Approximately 100,000 cutting marks, each 0.1 micrometers long and 0.08 micrometers deep, were created on one side of the dice. The processing time was approximately one hour.

In addition to brass, aluminum, stainless steel, and titanium can also be machined. It is expected that the processing time can be reduced to 30 minutes.

Related article (in Japanese) >>

■ World's "Fastest" Perfect Dice

A dice with its center of gravity as close as possible to the center.

99.99999999% precision!!

If you think of a cube divided into six square pyramids, the shape of the six holes carved into the bottom surface has been adjusted so that the weight of each square pyramid is equal.

The error in the distance between the center point of the dice in three dimensions and each face is within 2.23 microns, boasting precision that is no exaggeration to say is the best in the world. By making the holes as shallow as possible, we have succeeded in minimizing air resistance.

When six pyramids are combined, the design theory states that the distance from the center to each base will match 99.99999999% of the time.

It is also introduced in high school mathematics textbooks with images as "the fairest dice in the world."

Related article (in Japanese) >>

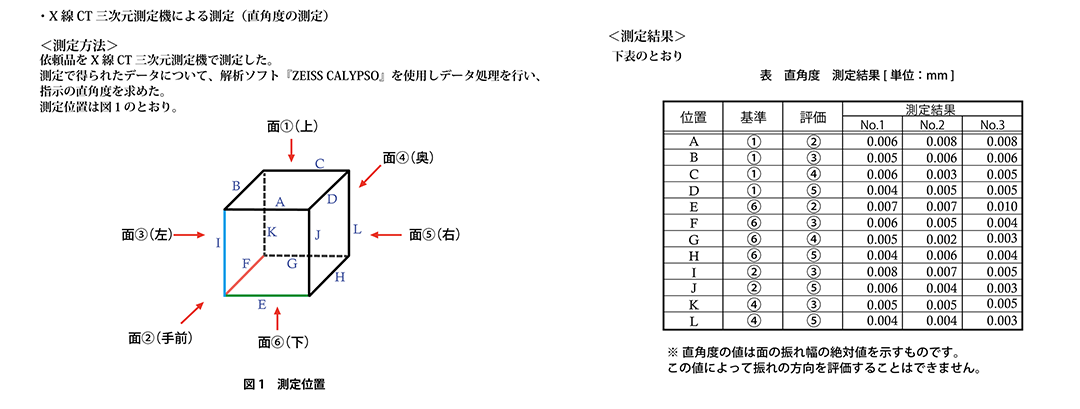

■ Measurement example of 0.3mm square samples

At the Saitama Industrial Technology Center, the following measurements and analysis carried out:

1) Shape measurement using an X-ray CT 3D measuring machine

2) Measurement using a non-contact micro shape measuring machine

3) Analysis of shape measurement data.

Measuring machine

- Carl Zeiss X-ray CT three-dimensional measuring machine METROTOM 800

- Taylor Hobson non-contact fine shape measuring machine Talysurf CCI 6000

Indoor temperature: 20±1 degrees Centigrade