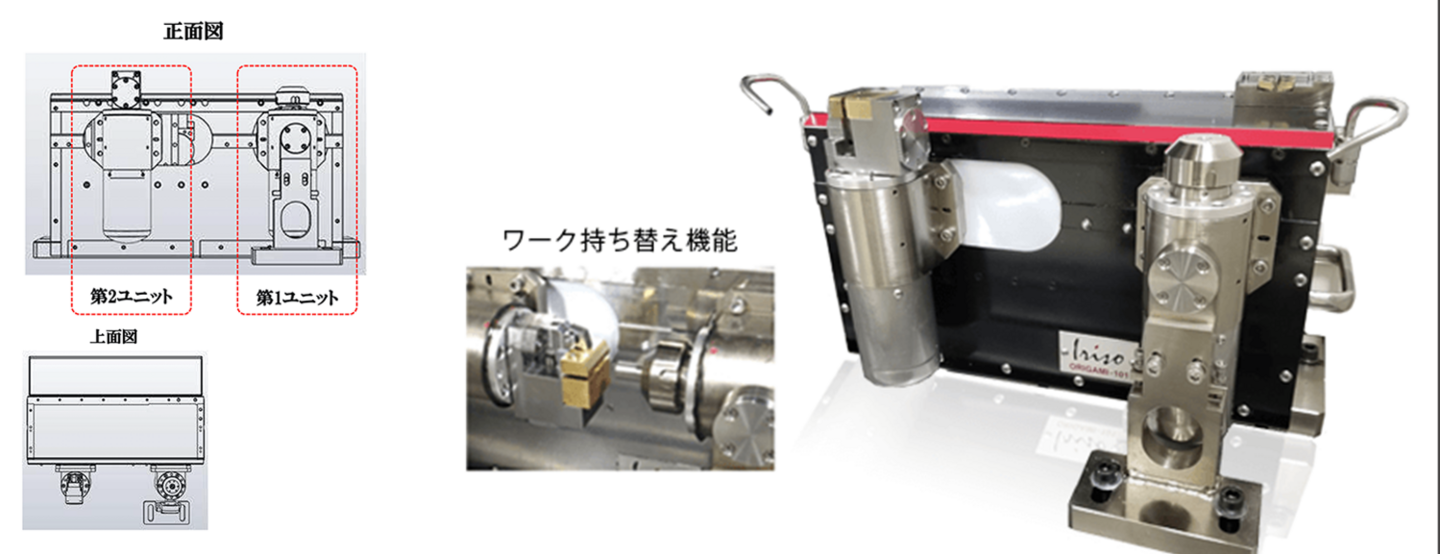

Outline of ORIGAMI

・Ultimate precision and amazing efficiency

・A device that automatically changes the workpiece during cutting

Machining of micro-components using MC is now possible! The automatic workpiece changing function reduces setup work and improves production technology for micro-component machining!

6-sided machining of 0.1mm to 10mm square can be automated.

[Features]

■Are you having trouble with the following?

✔︎ I want to automate the processing of workpieces under 5 mm that are difficult to handle and have previously relied on skilled craftsmen.

✔︎ I want to manufacture parts under 0.1 mm while maintaining a high process capability index.

✔︎ I want to try cutting materials in my own company that could not be processed with additive 3D printers.

✔︎ I want to perform stable cutting processing even in a small workplace where it is difficult to secure personnel.

✔︎ I want to make more advanced use of my current machining center.

■How to install and use

Required environment

- It is compatible with machining centers made 15 years ago.

- If you have a vertical 3-axis machining center, it can be easily installed and used.

- If you are in an environment that uses NC programs to operate 3-axis machining centers, it can be operated without having to learn a new programming language or make complex settings.

- There is no need for temperature control in the room, so no special environmental equipment is required.

System configuration example

- NV5000 (DMG Mori Seiki) Introduced in 2002, 12,000 r/min

*Can also be installed on machines with lower RPMs.

- If considering a 5-axis system, costs can be reduced by replacing it with a vertical 3-axis + ORIGAMI.

*For purchase of a new system, CMX 600 V (DMG Mori Seiki) is recommended.

Usage

When using ORIGAMI, we create a "jig" to hold the workpiece material in place, and also to move it. *The jig material corresponds with the product.

*Multiple templates of jig materials are available to match the shape of the workpiece to be processed. → Details >>